第三届陶瓷封装&微波陶瓷产业论坛

The 3rd Ceramic Packaging & Microwave Ceramic Industry Forum

邀请函

2025年12月11日 成都

会议背景

Part.1

随着5G/6G通信、物联网、人工智能、卫星通信、航空航天及高性能计算技术的飞速发展,微波射频器件正向高频化、小型化、高可靠性方向演进,微波介质陶瓷作为核心基础材料,其性能影响器件的信号传输质量、功耗与集成度,与此同时,陶瓷封装技术因具备优异的热导率、高频稳定性及气密性,成为高功率微波器件的首选解决方案。

With the rapid development of 5G/6G communications, the Internet of Things, artificial intelligence, satellite communications, aerospace, and high-performance computing technologies, microwave and RF devices are evolving toward higher frequencies, miniaturization, and higher reliability. As a core foundational material, the performance of microwave dielectric ceramics affects the signal transmission quality, power consumption, and integration level of these devices. Meanwhile, due to their excellent thermal conductivity, high-frequency stability, and hermeticity, ceramic packaging technologies have become the preferred solution for high-power microwave devices.

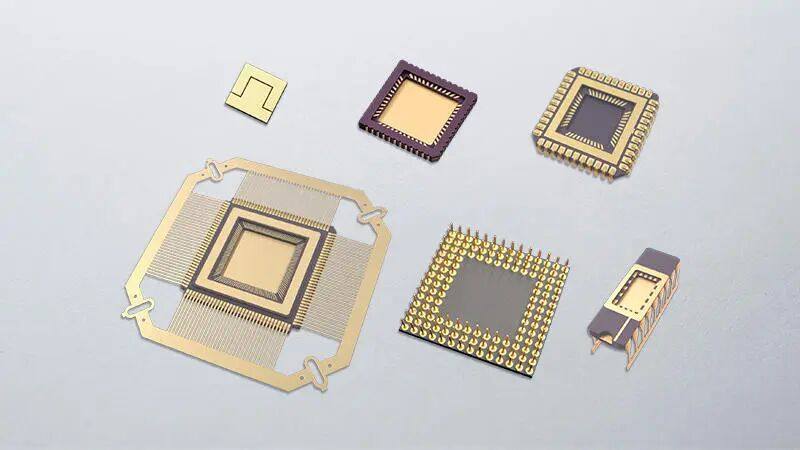

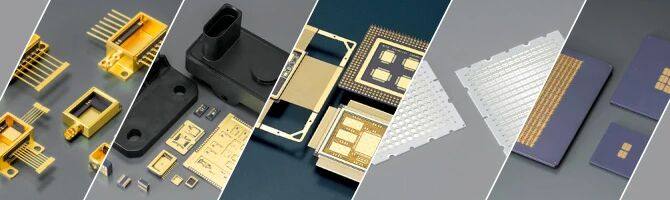

陶瓷封装以氧化铝(Al?O?)、氮化铝(AlN)等陶瓷材料为核心,为电子芯片提供保护的气密性封装技术,为芯片创造一個长期稳定、隔绝外界水汽和污染等工作环境,尤其适用于高可靠性和恶劣工况,凭借卓越的导热性、与芯片匹配的热膨胀系数、优异的电绝缘性、高机械强度和稳定的化学性能,在众多高端领域不可或缺;相较于成本更低的塑料封装,它性能更优但价格更高;相较于金属封装,它具有天然的绝缘优势。其主要工艺形式包括CDIP、CQFP、CLCC等封装,以及允许集成无源元件的LTCC(低温共烧陶瓷)和HTCC(高温共烧陶瓷)。

Ceramic packaging, primarily utilizing ceramic materials such as alumina (Al?O?) and aluminum nitride (AlN), is a hermetic packaging technology that provides protective encapsulation for electronic chips. It creates a long-term stable working environment isolated from external moisture and contaminants, making it particularly suitable for high-reliability applications and harsh operating conditions. Owing to its excellent thermal conductivity, coefficient of thermal expansion matching that of chips, outstanding electrical insulation, high mechanical strength, and stable chemical properties, it has become indispensable in many high-end fields. Compared to lower-cost plastic packaging, it offers superior performance but at a higher price. In contrast to metal packaging, it possesses inherent insulation advantages. Its main process forms include package types such as CDIP, CQFP, and CLCC, as well as LTCC (low-temperature co-fired ceramic) and HTCC (high-temperature co-fired ceramic), which allow for the integration of passive components.

陶瓷封装关键制造环节包括芯片贴装、引线键合以及保证可靠性的密封(如平行缝焊)和气密性检漏。成为航空航天、军事装备、植入式医疗设备、5G通信基站、新能源汽车功率模块等高可靠性、高频、高功率应用的首选方案,未来,其发展正朝着高密度集成、先进材料应用和成本控制的方向演进。

The key manufacturing steps of ceramic packaging include die attachment, wire bonding, and reliability assurance processes such as hermetic sealing (e.g., parallel seam welding) and leak detection. It has become the preferred solution for applications requiring high reliability, high frequency, and high power, such as aerospace, military equipment, implantable medical devices, 5G communication base stations, and new energy vehicle power modules. In the future, its development is moving toward higher integration density, advanced material applications, and cost control.

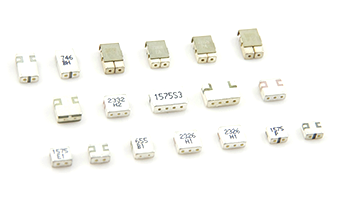

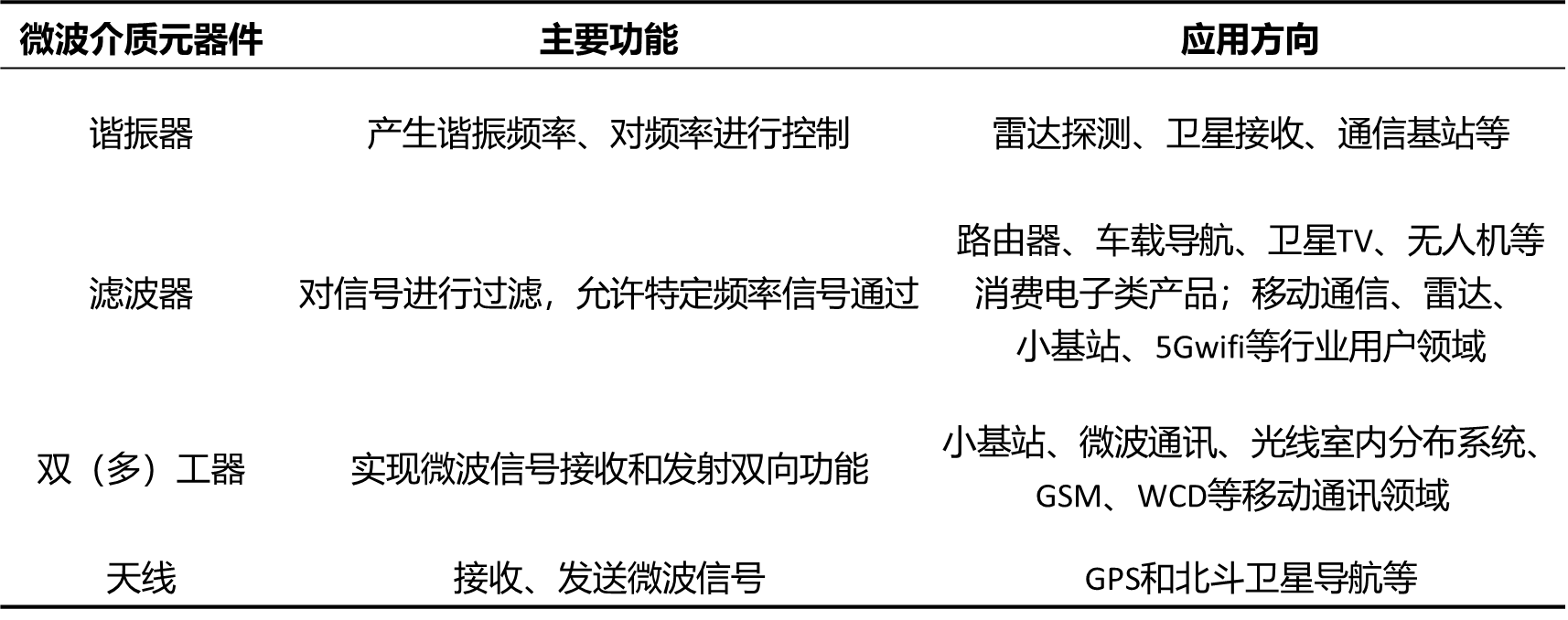

微波介质陶瓷(MWDC)是应用于微波频段(主要是UHF、SHF频段,300MHz~300GHz)电路中作为介质材料并完成一种或多种功能的陶瓷,作为一种重要的电子陶瓷材料,微波介质陶瓷具有介电常数高、谐振频率温度系数小、介质损耗低等众多特点。

Microwave Dielectric Ceramics (MWDC) refer to ceramic materials used in microwave frequency circuits (primarily in the UHF and SHF bands, 300 MHz to 300 GHz) as dielectric materials to perform one or more functions. As an important type of electronic ceramics, microwave dielectric ceramics exhibit notable characteristics such as high dielectric constant, low temperature coefficient of resonant frequency, and low dielectric loss.

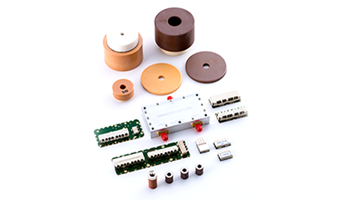

介质谐振器产品

介质低通滤波器产品

微波介质工艺技术包括制备各种介电常数的高温烧结陶瓷粉,并通过成型、烧结、研磨、制电极、组装、调试等工艺,生产出微波频率器件,微波介质陶瓷坯体在1200℃以上温度烧结而成,具有高Q值、小尺寸、低温度系数等优势。

The process technology of microwave dielectric ceramics involves the preparation of ceramic powders with various dielectric constants through high-temperature sintering. These powders are then shaped, sintered, ground, electroded, assembled, and tuned to produce microwave frequency devices. The green bodies of microwave dielectric ceramics are sintered at temperatures above 1200°C, offering advantages such as high Q values, compact size, and low temperature coefficient.

基于优异的微波介电性能,微波介质陶瓷元器件目前广泛应用于移动通信、卫星通讯、卫星导航与定位、航空航天、电子器件、汽车工业、万物互联等领域。其中,移动通信领域是微波介质陶瓷元器件的重要应用方向;介质谐振器、介质滤波器、介质双工器、介质多工器等均是通信基站的重要元器件。

Owing to their excellent microwave dielectric properties, microwave dielectric ceramic components are now widely used in fields such as mobile communications, satellite communications, satellite navigation and positioning, aerospace, electronic devices, automotive industry, and the Internet of Things. Among these, mobile communications represent a major application area for microwave dielectric ceramic components. Key devices such as dielectric resonators, dielectric filters, dielectric duplexers, and dielectric multiplexers are essential components in communication base stations.

在无线通信领域,微波陶瓷用于滤波器、谐振器等组件,提高信号处理效率;陶瓷封装保护射频芯片,确保小型化与稳定性。在卫星通信与导航系统中,微波陶瓷保证信号稳定性,陶瓷封装则通过气密性提升环境适应能力,广泛应用于导航设备。雷达与军事领域中,微波陶瓷实现精确信号处理,陶瓷封装增强抗干扰性和环境适应性。

In the field of wireless communications, microwave ceramics are used in components such as filters and resonators to enhance signal processing efficiency, while ceramic packaging protects RF chips, ensuring miniaturization and stability. In satellite communication and navigation systems, microwave ceramics ensure signal stability, and ceramic packaging improves environmental adaptability through its hermetic properties, making it widely applicable in navigation equipment. In radar and military applications, microwave ceramics enable precise signal processing, and ceramic packaging enhances anti-interference capabilities and environmental resilience.

为加强陶瓷封装&微波陶瓷行业上下游交流联动,九游老哥J9俱乐部官网智造将于12月11日在成都举办第三届陶瓷封装&微波陶瓷产业论坛,论坛的主题将围绕陶瓷封装&微波陶瓷创新材料、先进工艺、前沿应用等方面展开,诚挚邀请产业链上下游企业及高校研究所与会交流,共同探讨陶瓷封装&微波陶瓷产业的最新技术进展和未来发展趋势。

To enhance communication and collaboration across the ceramic packaging and microwave ceramics industry chain, Aibang Intelligent Manufacturing will host the 3rd Ceramic Packaging & Microwave Ceramics Industry Forum on December 11 in Chengdu. The forum will focus on innovative materials, advanced processes, and cutting-edge applications in ceramic packaging and microwave ceramics. We cordially invite enterprises, universities, and research institutes throughout the industry chain to participate, exchange insights, and jointly explore the latest technological advancements and future development trends in the ceramic packaging and microwave ceramics sector.

会议议程

Part.2

2025年12月10日(周三):14:00-18:00 签到

2025年12月11日(周四):7:30-9:00 签到;8:50-18:00 会议;18:00-20:30 晚宴?

??Wednesday, December 10, 2025:?? 14:00-18:00 Registration

??Thursday, December 11, 2025:?? 7:30-9:00 Registration; 8:50-18:00 Conference Sessions; 18:00-20:30 Banquet Dinner

拟定议题

Part.3

|

序号 |

拟定议题 |

拟邀嘉宾 |

|

1 |

系统级封装用陶瓷材料研究进展和发展趋势 Research Progress and Development Trends of Ceramic Materials for System-in-Package (SiP) |

拟邀请陶瓷封装企业/高校研究所 ??Proposed Invitations: Ceramic Packaging Enterprises/Universities & Research Institutes |

|

2 |

微波陶瓷在毫米波雷达中的技术研究与应用 Research and Application of Microwave Ceramics in Millimeter-Wave Radar Technology |

拟邀请微波介电陶瓷材料企业/高校研究所?? Proposed Invitations: Microwave Dielectric Ceramic Enterprises/Universities & Research Institutes? |

|

3 |

三维集成陶瓷封装技术的挑战与解决方案 Challenges and Solutions in 3D Integrated Ceramic Packaging Technology |

拟邀请陶瓷封装企业/高校研究所 List of Proposed Invitees: Ceramic Packaging Enterprises/Universities & Research Institutes |

|

4 |

集成电路陶瓷封装的发展概况 Development Overview of Ceramic Packaging for Integrated Circuits |

拟邀请陶瓷封装企业/高校研究所?? Proposed List of Invitees: Ceramic Packaging Enterprises/Universities & Research Institutes? |

|

5 |

5G/6G基站用微波陶瓷滤波器的应用 Applications of Microwave Ceramic Filters in 5G/6G Base Stations |

拟邀请微波滤波器企业/高校研究所 Proposed List of Invitees: Microwave Filter Enterprises/Universities & Research Institutes? |

|

6 |

新型微波介质陶瓷材料的研究进展 Research Progress on Novel Microwave Dielectric Ceramic Materials |

拟邀请微波介电陶瓷材料企业/高校研究所 List of Proposed Invitees: Microwave Dielectric Ceramic Enterprises/Universities & Research Institutes |

|

7 |

微波陶瓷在介质谐振器中的应用研究 Research on the Application of Microwave Ceramics in Dielectric Resonators |

拟邀请微波介电陶瓷企业/高校研究所 ??Proposed List of Invitees: Microwave Dielectric Ceramic Enterprises/Universities & Research Institutes? |

|

8 |

铜浆在多层陶瓷封装外壳制备技术中的研究与应用 Research and Application of Copper Paste in the Fabrication Technology of Multilayer Ceramic Packaging Shells |

拟邀请陶瓷封装/浆料企业/高校研究所 List of Proposed Invitees: Ceramic Packaging/Paste Enterprises/Universities & Research Institutes |

|

9 |

低温共烧陶瓷基板及其封装应用 Low-Temperature Co-fired Ceramic (LTCC) Substrates and Their Packaging Applications |

拟邀请陶瓷封装企业/高校研究所 ??Proposed List of Invitees: Ceramic Packaging Enterprises/Universities & Research Institutes?? |

|

10 |

微波烧结技术制备微波介质陶瓷的工艺介绍 Process Introduction of Microwave Sintering Technology for Preparing Microwave Dielectric Ceramics |

拟邀请微波介电陶瓷企业/高校研究所 Proposed List of Invitees: Microwave Dielectric Ceramic Enterprises/Universities & Research Institutes? |

|

11 |

低温玻璃-陶瓷封装技术的研究进展 Research Progress in Low-Temperature Glass-Ceramic Packaging Technology |

拟邀请陶瓷封装企业/高校研究所 List of Proposed Invitees: Ceramic Packaging Enterprises/Universities & Research Institutes |

|

12 |

电子封装陶瓷基板流延成型工艺及装备 Tape Casting Process and Equipment for Electronic Packaging Ceramic Substrates |

拟邀请陶瓷封装企业/高校研究所 ??Proposed List of Invitees: Ceramic Packaging Enterprises/Universities & Research Institutes? |

|

13 |

微电子陶瓷封装的金属化技术研究进展 Research Progress in Metallization Technology for Microelectronic Ceramic Packaging |

拟邀请陶瓷封装企业/高校研究所 List of Proposed Invitees: Ceramic Packaging Enterprises/Universities & Research Institutes |

|

14 |

高介电常数微波陶瓷材料的开发与应用 Development and Application of High Dielectric Constant Microwave Ceramic Materials |

拟邀请微波介电陶瓷材料企业/高校研究所 ??Proposed List of Invitees: Microwave Dielectric Ceramic Enterprises/Universities & Research Institutes? |

|

15 |

陶瓷封装技术在传感器领域的技术与应用 ??Ceramic Packaging Technology and Its Applications in the Sensing Field?? |

拟邀请陶瓷封装企业/高校研究所 Proposed List of Invitees: Ceramic Packaging Enterprises/Universities & Research Institutes |

|

16 |

微波陶瓷在医疗成像设备中的应用 Application of Microwave Ceramics in Medical Imaging Equipment |

拟邀请微波介电陶瓷企业/高校研究所 Proposed List of Invitees: Microwave Dielectric Ceramic Enterprises/Universities & Research Institutes? |

|

17 |

高密度陶瓷封装散热技术产业方案 Industrial Solutions for Thermal Management in High-Density Ceramic Packaging |

拟邀请陶瓷封装企业/高校研究所 Proposed List of Invitees: Ceramic Packaging Enterprises/Universities & Research Institutes |

|

18 |

低介电常数、低损耗封装陶瓷的开发与应用 Development and Application of Low Dielectric Constant, Low Loss Packaging Ceramics |

拟邀请陶瓷封装企业/高校研究所 Proposed List of Invitees: Ceramic Packaging Enterprises/Universities & Research Institutes |

|

19 |

微型化微波滤波器中陶瓷材料的创新应用 Innovative Applications of Ceramic Materials in Miniaturized Microwave Filters |

拟邀请微波介电陶瓷企业/高校研究所 Proposed List of Invitees: Microwave Dielectric Ceramic Enterprises/Universities & Research Institutes? |

|

20 |

传感器技术的发展及陶瓷封装的应用趋势 Development of Sensor Technology and Application Trends of Ceramic Packaging |

拟邀请传感器/封装企业/高校院所 List of Proposed Invitees: Sensor/Packaging Enterprises/Universities & Research Institutes |

|

21 |

微波介质陶瓷薄膜的沉积技术与集成应用Deposition Techniques and Integrated Applications of Microwave Dielectric Ceramic Thin Films |

拟邀请微波介电陶瓷企业/高校研究所 Proposed List of Invitees: Microwave Dielectric Ceramic Enterprises/Universities & Research Institutes? |

?

更多议题征集中,欢迎推荐或自拟议题,演讲/赞助请联系李小姐:18124643204

More topics are now being collected. We warmly welcome recommendations or self-proposed topics. For speaking/sponsorship opportunities, please contact Ms. Li at +86 18124643204

拟邀请企业类型

Part4

通讯、基站、消费电子、汽车电子、LED、功率半导体器件、光通信等终端企业;陶瓷封装、陶瓷基板及覆铜板、LTCC、HTCC、薄膜基板、厚膜基板等生产企业;氧化铝、氮化铝、氮化硅、氧化铍、玻璃粉等陶瓷材料企业;金属铜箔、金属焊料、金属浆料等材料企业;陶瓷粉体生产配制设备、砂磨机、干压机、流延机、抛光研磨设备、打孔设备、切割设备、激光设备、填孔设备、丝网印刷机、叠层机、等静压机、磁控溅射设备、显影设备、去膜设备、蚀刻设备、电镀设备、排胶炉、烧结炉、钎焊炉、X-RAY、AOI、超声波扫描显微镜、测厚仪、热循环测试设备、剥离强度测试仪、氦质谱检漏仪、自动化组装、清洗设备等设备企业;助剂、电镀液、研磨液、网版、保护膜、耐火材料等材料企业;检测、科研院所、高校机构等。

Terminal application enterprises in fields such as communications, base stations, consumer electronics, automotive electronics, LEDs, power semiconductor devices, and optical communications;

Production process enterprises specializing in ceramic packaging, ceramic substrates and copper-clad laminates, LTCC, HTCC, thin-film substrates, and thick-film substrates;

Ceramic material enterprises focusing on alumina, aluminum nitride, silicon nitride, beryllium oxide, glass powders, etc.;

Material enterprises supplying metal copper foils, metal solders, metal pastes, etc.;

Equipment enterprises providing ceramic powder production and formulation equipment, sand mills, dry presses, tape casting machines, polishing and grinding equipment, drilling machines, cutting machines, laser equipment, hole-filling equipment, screen printing machines, laminating machines, isostatic presses, magnetron sputtering equipment, developing machines, film removal equipment, etching equipment, plating equipment, debinding furnaces, sintering furnaces, brazing furnaces, X-RAY, AOI, ultrasonic scanning microscopes, thickness gauges, thermal cycle testing equipment, peel strength testers, helium mass spectrometers leak detectors, automated assembly systems, cleaning equipment, etc.;

Material enterprises specializing in additives, plating solutions, grinding fluids, screen meshes, protective films, refractory materials, etc.;

Testing institutions, research academies, and university organizations.

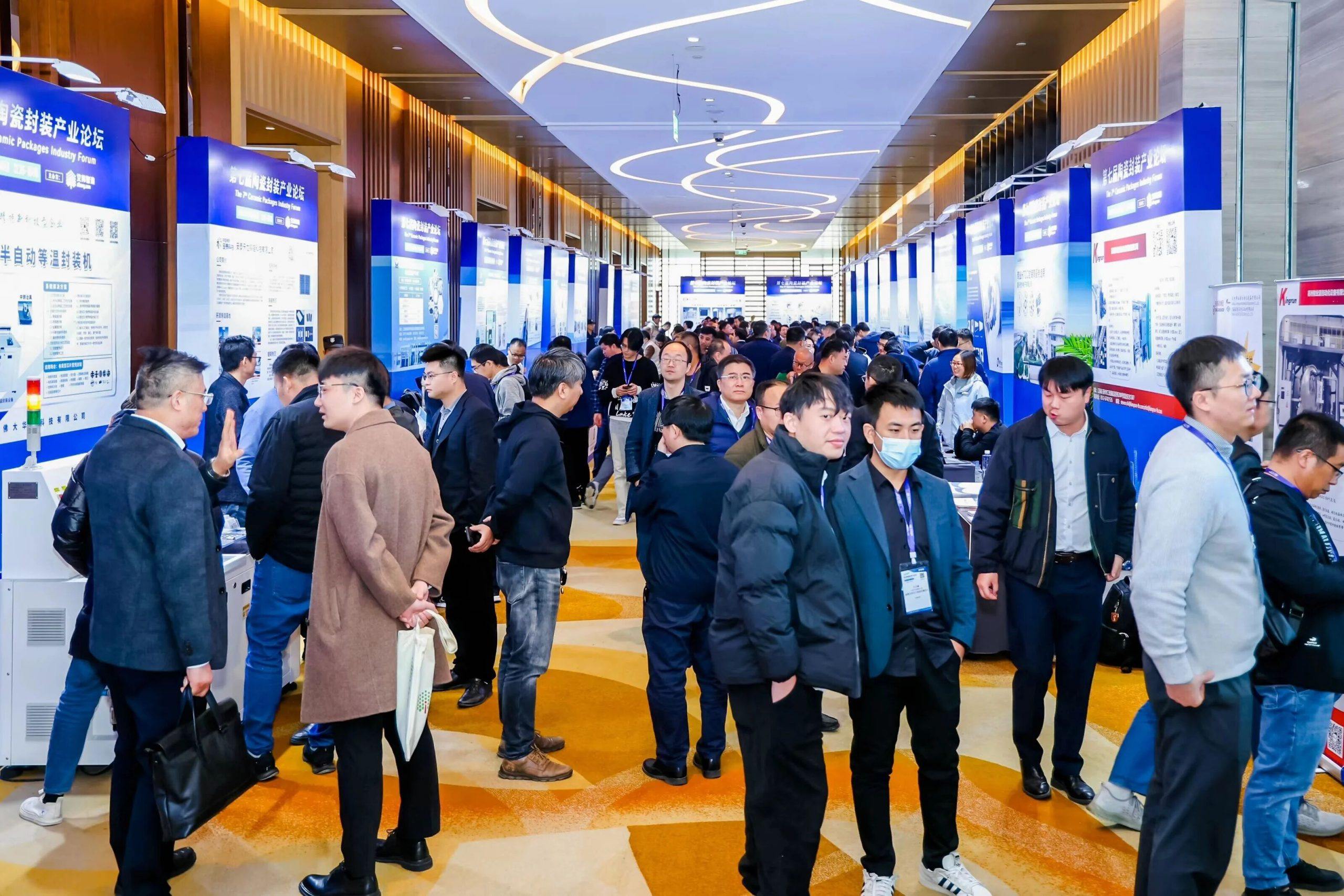

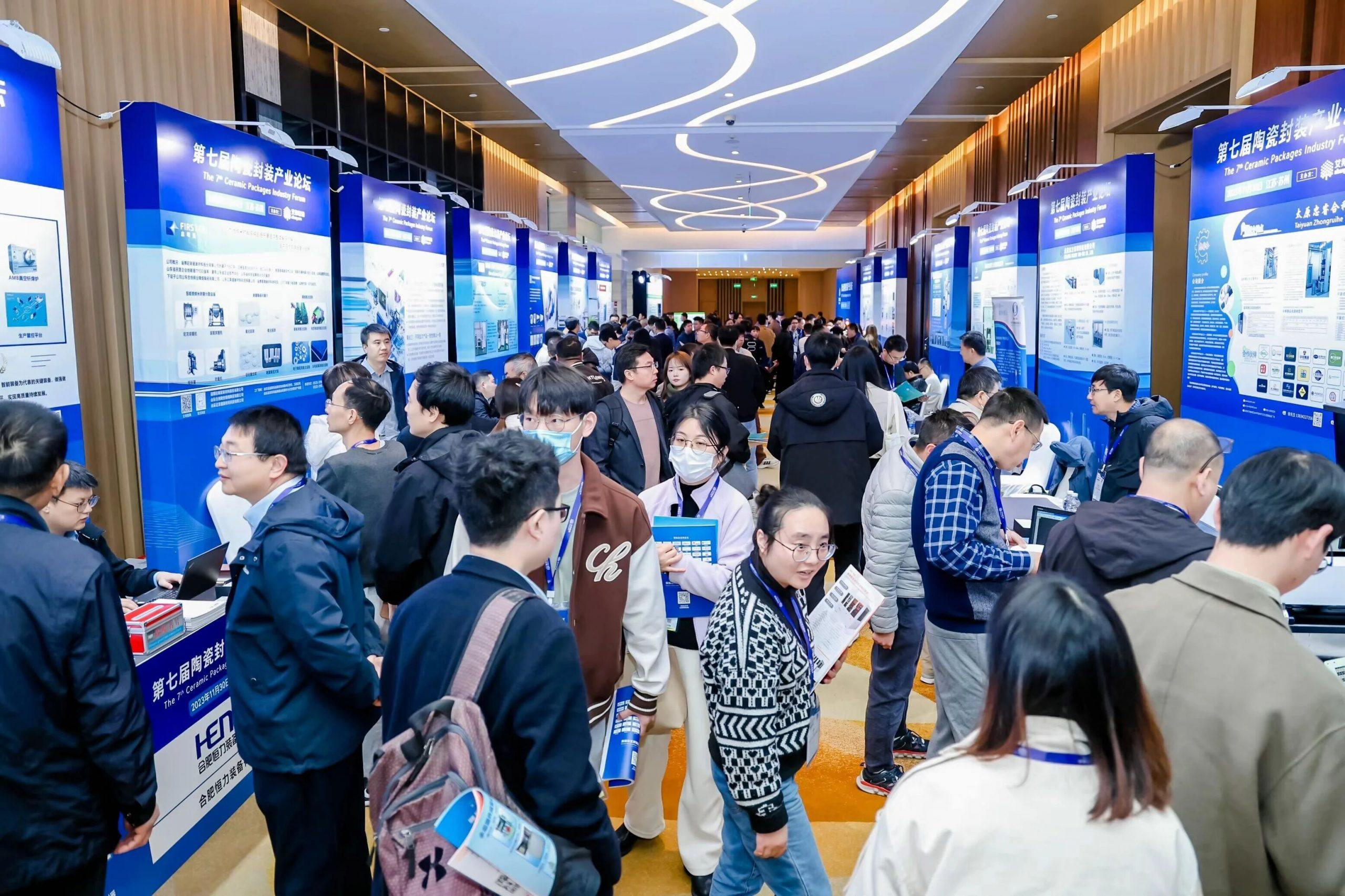

往届活动回顾

Part.1

△往届活动现场??Past Event Highlights?

(

左右滑动查看更多

)

△往届演讲嘉宾Past Speakers

?往届赞助单位

Part.6

报名方式

Part.7

方式一:

温小姐:18126443075(同微信)

邮箱:ab057@aibang.com

扫码添加微信,咨询会议详情

??Option 1:??

??Contact: Ms. Wen??

??Tel/WeChat:?? +86 18126443075

??Email:?? ab057@aibang.com

??Scan the QR code to add WeChat for conference details:??

注意:每位参会者均需要提供信息

方式二:长按二维码扫码在线登记报名

Note:?? Each attendee must provide their information.

??Option 2:??

??Long press the QR code to scan and register online:?

或者复制网址到浏览器后,微信注册报名

Copy the URL to your browser and register via WeChat:

https://www.aibang360.com/m/100270?ref=172672

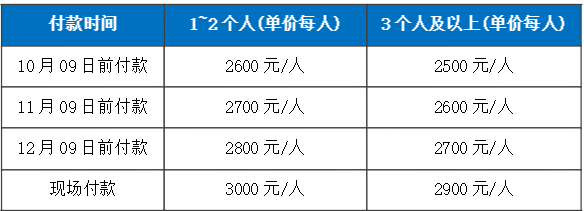

收费标准

Part.8

★费用包括会议门票、全套会议资料、午餐、茶歇等,但不包括住宿。

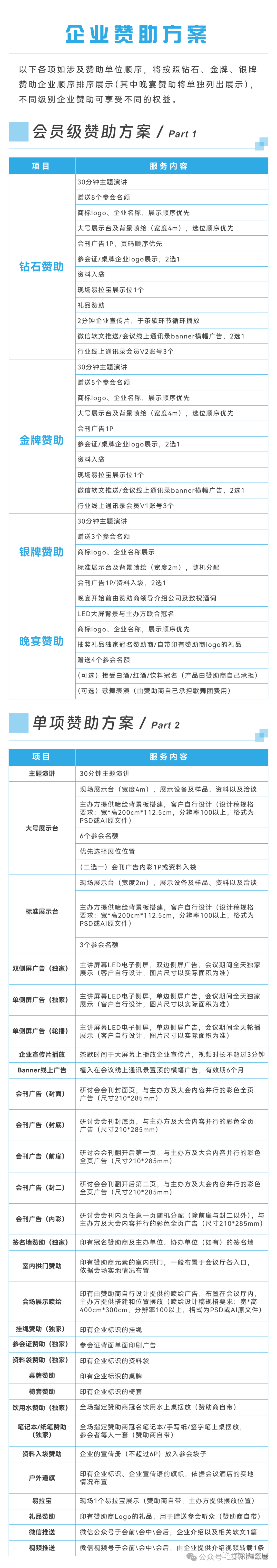

赞助方案

Part.9

阅读原文,即可报名

长按识别二维码关注公众号,点击下方菜单栏左侧“微信群”,申请加入交流群。